Introduction to the Equipment CO2 Calculator

Summary

Introduction

The Equipment CO2 Calculator is a tool to estimate the climate change impact of various types of products used in the construction sector:

- Construction machines and equipment;

- Powered access, forklifts & telehandlers;

- Power and temperature control;

- Smaller equipment and tools;

- Modular and sanitary space.

The entire life cycle is within the scope, but the calculator is specifically designed to assess the use phase.

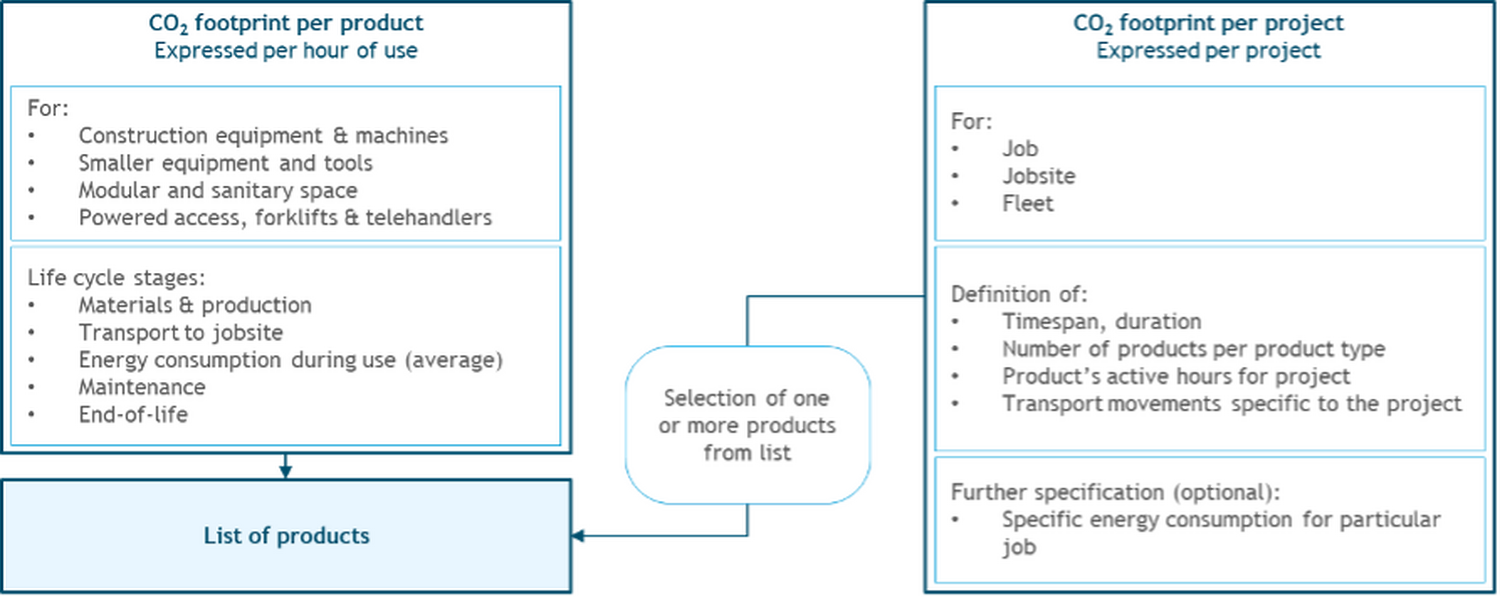

- The CO 2 footprint per product. Here products are defined. The CO2 footprint is expressed per hour of use of the product. Products variants can be compared.

- The carbon footprint of a construction project. Taking the products as a starting point, this calculator defines construction projects, big and small, performed with one or more products. Such as: a job for a particular product, an entire jobsite with a variety of products working on one or several construction works. It can also be used to calculate the CO 2 footprint of a fleet in a certain year. The CO2 footprint represents the project (job, jobsite or fleet), characterized by a certain duration of the job or timespan. The user can compare various scenarios or product combinations.

In chapter 3 and 4 both calculator parts are described in detail.

General methodology

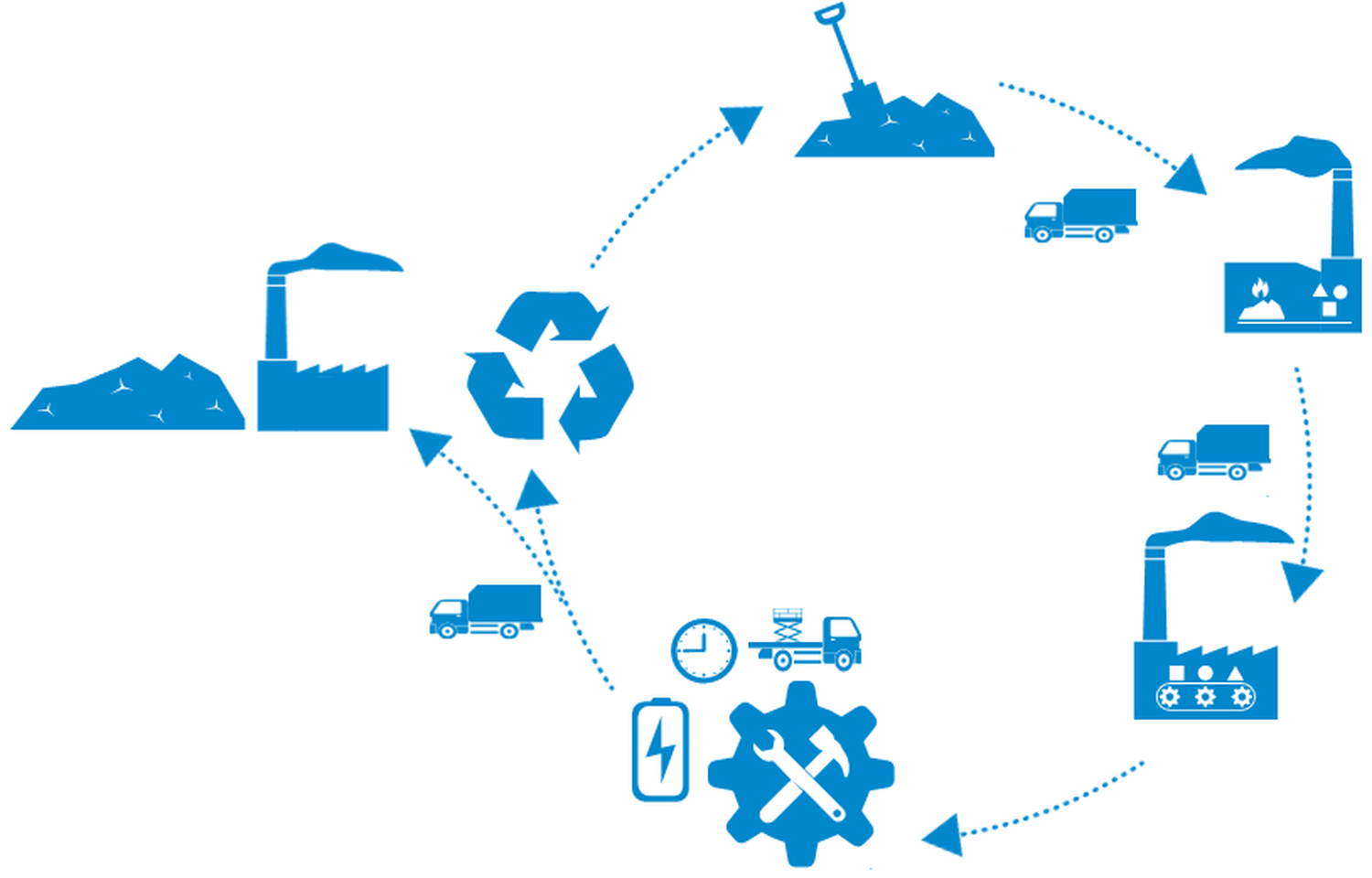

The Equipment CO2 Calculator requires information regarding the product’s characteristics and use. The user is guided through the life cycle, step by step. The information entered by the user is combined with background data to estimate the carbon footprint of a product and/or a project.

Figure 1 – Visual representation of the lifecycle of a product

Carbon footprint: impact on climate change

The Equipment CO2 Calculator calculates the impact on climate change of using the product. ‘Impact on climate change’ is also often referred to as the carbon footprint of a product. The carbon footprint measures the contribution of a product to global climate change through the emission of greenhouse gases.

In the Equipment CO2 Calculator, all greenhouse gases are taken into account. CO2 or carbon dioxide is the most important and well-known greenhouse gas. Other important greenhouses gases include methane (CH4) and dinitrogen monoxide (N2O). These other gas emissions are included and expressed in the final result in their CO2 equivalent.

Carbon footprint per product

Purpose

The calculator estimates the carbon footprint of a product per hour of use. Expressing the results per hour of (active) use enables comparisons across different types of products and over a wide range of ownership scenarios. The Equipment CO2 Calculator can be used to evaluate a single ownership period of product. The calculator’s results can for instance be used to:

- Investigate which part of the life cycle has the largest contribution to the carbon footprint;

- Compare different use scenarios for a product; - Study the effects of changes to a baseline use scenario, such as measures to reduce the footprint;

- Evaluate the effects of alternative fuel consumption.

The first part of the Equipment CO2 Calculator is designed to assess the carbon footprint of one product. Construction equipment is often owned by various owners before finally being discarded. The calculator can be used by any owner within the total life span of the product.

The life cycle

The Equipment CO2 Calculator considers the carbon footprint of the whole life cycle. The results encompass the manufacturing of the product, the use phase and end-of-life treatment. The Calculator is specifically designed to assess the impact of use scenarios. The user can specify key parameters:

- lifetime and utilization

- transport to/from the job site

- energy consumption (type and efficiency)

- motor oil consumption

From user input to carbon footprint per hour of use

The calculator’s results are expressed per hour of active use of the product. This is done to enable fair comparison between use scenarios. In addition, this makes it possible to use the tool for any ownership period.

For better understanding, the figure below shows an example how information in the calculator is translated to the impact per hour.

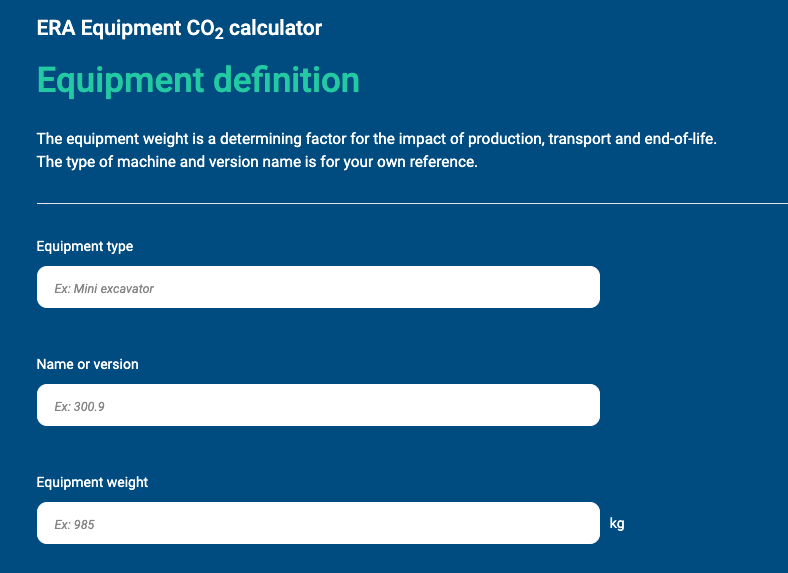

Getting started: Product definition

The starting point of the calculator is the definition of the product. The calculator requires basic information of the product:

The Type of product and the Version and Name are entered as a reference for the user. This information is shown on the results screen and is used when saving your entry. It is not used for any calculations.

The Product weight (in kg) is an important parameter in the calculator. The calculator uses it to determine the load factor of trucks for transportation. In addition, it can be used to estimate the impact of the production and end-of-life life cycle stages of the product in Step 1 (if no existing LCA covering these phases is available).

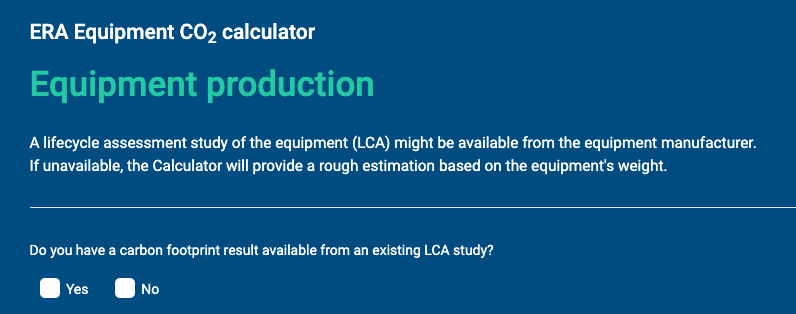

Step 1: Production

The production phase encompasses all steps from raw material extraction up to the point that the product leaves the OEM’s factory. The carbon footprint of production therefore covers raw material extraction, production of intermediates, product part manufacturing, assembly and all transport steps in between. This corresponds to a so-called ‘cradle-to-gate’ life cycle assessment.

The calculator offers two options to determine the carbon footprint of production:

1. Entering results from an existing LCA (cradle-to-gate);

2. Using the product’s weight to estimate the carbon footprint.

1. Entering results from an existing LCA

If an LCA has already been carried out for the product, the carbon footprint results can be entered in the Equipment CO2 Calculator. If an LCA is available, it is advised to use this option.

Note that the LCA must meet some conditions to be usable:

- The LCA should report a carbon footprint result (‘impact on climate change’, ‘global warming potential’). This result is expressed in kilograms CO2-equivalent;

- The LCA result corresponds to one product;

- Ideally, the LCA applies to the specific product being evaluated in the Equipment CO2 Calculator. If an LCA for a similar product is available (with similar weight and material composition), this can be used as a fall-back option. However, this may affect the accuracy of the overall results.

- Scope:

- The LCA should contain all relevant life cycle steps from cradle-to-gate;

- The LCA should include the impact of energy consumption, use of auxiliary materials/chemicals, water consumption, final waste treatment of material losses and transportation or raw materials and parts;

- Note that in Step 1, only the carbon footprint of production (cradle-to-gate) should be entered. Any climate change impact related to the use phase and end-of-life should be excluded. If the existing LCA also included the end-of-life, these carbon footprint results can be entered in Step 6.

2. Using a weight-based estimate

The second option is to use the product’s weight (entered in Step 0) to calculate the carbon footprint of production. The calculator does this in the background, and no further user input is required.

Please note that using the weight-based approach provides a first estimate of the carbon footprint of production. It can be used as an indication, but is not as accurate as a product-specific LCA study. However, for many products, the production phase is not the most important life cycle stage per hour of use.

Weight-based estimate of construction equipment

The composition is obtained by OEMs for eight types of construction equipment, via LCAs performed for ERA in 2019 by SGS Search. As a baseline, diesel-powered equipment is modelled and assessed. Then distinction is made between 1) a diesel engine, 2) a Li-ion battery and hybrid equipment, and 3) a lead acid battery. This variation is done based on LCA results of comparable equipment (diesel vs alternative power) by one OEM, and material composition information by another OEM of diesel powered and battery electric variants of the same equipment.

Based on all information provided, CE Delft has determined the following:

- For diesel-powered machines we arrive at an impact of 2.2 kg CO2-eq. per kg of product.

- On average, Li-ion battery electric machines have 40% higher material footprint. The results show a range: the impact of Li-ion compared to diesel is between 22 and 82% higher according to data from one OEM –- average 42% -- whereas results from the other OEM show an 37% increase. Based on this, we have selected a 40% increase for the calculator.

- The comparative study by one of the OEMs suggests that for 10.000 h of use, one Li-ion battery is required, but two lead-acid batteries. In impact per kg of lead-acid powered machines we take into account that 2 batteries are needed. Based on a similar lifetime, a lead battery powered machine has an on average 7% higher impact compared to a Li-ion battery powered machine (range 0 to 28%).

The composition is obtained by OEMs for two types of smaller equipment and tools, via LCAs performed for ERA in 2019 by SGS Search. Because of the small amount of data points (two products) no further distinction was made between corded and battery powered tools. As this value is based on only two products, the value is uncertain. Users should be encouraged to ask OEMs for LCA results of specific products.

Weight-based estimate of modular and sanitary space

The composition of two mainly used types of modular space – wood-based and steel-based, was obtained via two OEMs. The two products (steel- and wood-based) were modelled in Simapro LCA software and the LCA results were calculated. So an LCA model of each variant is available at CE Delft.

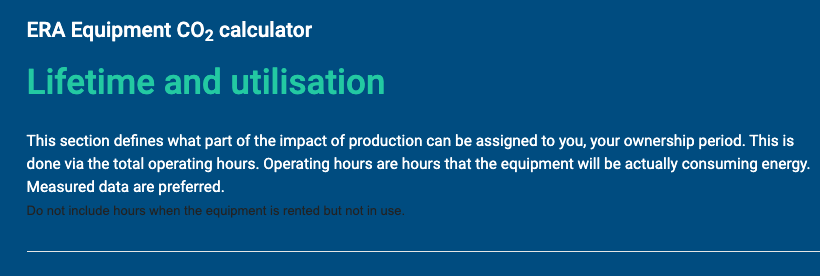

Step 2: Lifetime and utilisation

The information asked for in this step determines the total expected operating hours during the time the product is in ownership. This then is used to define the impact of the product’s materials and end-of-life treatment per hour of use.

Important: the operating hours are the hours the product is actively in use. It does NOT represent the full amount hours that the product is rented to a third party.

The parameters are made specific per product type, to guide the user towards the total expected operating hours.

Construction equipment

The calculator requests three parameters regarding the lifetime and utilisation of the construction equipment:

- total expected operating hours in total lifetime of the equipment;

- ownership period in years;

- total expected operating hours used during your company's ownership.

In the Equipment CO2 Calculator, the production and end-of-life impacts are therefore divided over the entire lifetime of the machine. If a machine is for instance expected to run for 10,000 hours during its life and one company uses it for 5,000 hours, this company is responsible for 50% of the impact of the production and end-of-life stages.

Table 3 provides common sources for deriving the values.

Table 3 - Sources that the user may consult for information

| Parameter | Source(s) |

|---|---|

| Total expected operating hours in total lifetime of the equipment |

OEM technical specifications |

| Ownership period in years |

Owner experience |

| Total (expected) operating hours used during your company's ownership |

Based on measurements or expert estimates |

Handheld tools

For handheld tools the calculator works with the total expected operating hours, regardless of the ownership. This implies that all impact is assigned to the first owner of the product. For battery-electric handheld tools, the user is guided to determine the total expected operating hours, via three parameters specified to this kind of product.

Modular and sanitary space

For modular and sanitary space, the user is guided to determine the total expected operating hours for a particular ownership period, via four parameters and two questions, specified to this kind of product.

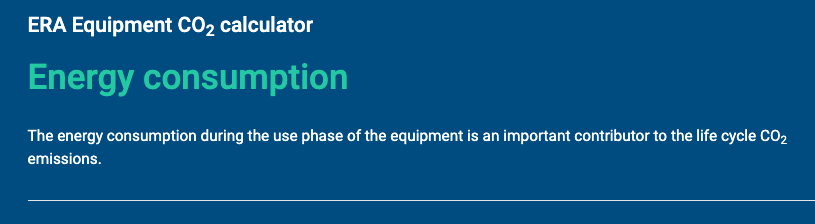

Step 3: Energy consumption

This part of the calculation focuses on the energy consumption of the product during its use. In the calculator, the user selects the energy type (fuel or electricity), defines the average energy consumption per hour and can select renewable options (renewable electricity and biofuel).

Energy consumption

Some products consume fuel, others electricity; modular spaces may consume both. For smaller eqiupment and tools a distinction is made between products with a battery and with a cord. The data asked for by the calculator (parameters) made are specific to the type of product. For battery powered smaller equipment and tools, the user is guided toward the energy consumption via the fields "battery voltage", "battery capacity" and an estimation of the use time: "hours per charge".

It is preferred to use measured data for the energy consumption. This can for instance be derived using fuel receipts, electricity bills for a certain period of time (month, year) or power consumption measurements, divided by the actual operating hours during that period of time. Second best is an expert estimate based on practice or an estimate based on OEM technical data.

For battery powered electric equipment this functionality will be made available in the next versions of the CO2 Calculator (v.3). For now, we advise the users to calculate the energy consumption in kWh/h as follows:

kWh per hour of use = Voltage (V) * Capacity (Ah) / hours of use per charge (h) /1000

Important: work with the average consumption per hour. When making an estimate: be sure to also account for fuel or electricity consumption during idle time.

Type of fuel and electricity

For fuel, the calculator enables the user to select the share of biodiesel in the fuel blend.

For instance: if you use B7 fuel, the biodiesel share is 7%; if you use B30 fuel, the biodiesel share is 30%.

For electricity, the country of its origin is asked for. The country of origin defines the impact of carbon footprint per kWh, since the composition if the electricity mix differs per country. A box for 100% renewable electricity can be ticked.

Important: renewable electricity should only be selected if the owner of the product is responsible for the generation of the electricity. If you buy electricity off the grid, even from a supplier that generates renewable energy, do not tick the box.

Hydrogen as fuel and electrification of fuel-powered equipment

The calculator also enables users to assess the effects of various sustainability measures. It provides indicative results, based on literature, for:

- what if the equipment would be powered by hydrogen instead of diesel fuel?

- electrification: what if the equipment would be powered by electricity instead of diesel;

- a different energy source: hydrogen instead of diesel

- the parts for power and transmission change: from an engine and fuel tank to a fuel cell and hydrogen tank.

- a different energy source: electricity instead of diesel

- different parts for power and transmission: from an engine and fuel tank to a electromotor, battery and wiring.

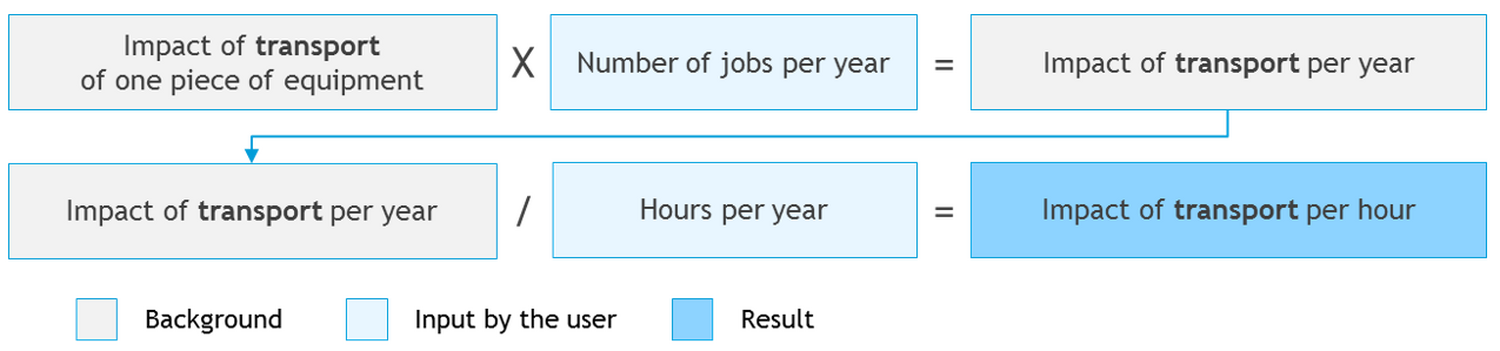

Step 4: Transport

In this step, information is gathered to assess the carbon footprint of transporting the product to and from construction sites. The impact of transportation arises from the diesel consumption of the truck or van which is used for transportation. In the Equipment CO2 Calculator, the impact of transportation is calculated using four user inputs:

- the load capacity of the truck/van, in tonne;

- the load factor, as a percentage;

- the (one-way) distance over which the product is transported to a construction site, in kilometre;

- The number of jobs per year.

The load capacity is the nominal weight that the vehicle can transport. For example, a large van has a load capacity of 1.2 tonnes, whereas a large truck has a load capacity of 13 tonnes (excluding a trailer).

The load factor expresses how full the vehicle transporting the product typically is. A value of 100% means that the vehicle is loaded to the maximum of its load capacity. For example: a truck with a load capacity of 10 tonnes carrying only a 3 tonne boom lift, has a load factor of 30%. However, if the trucks are typically carrying several boom lifts and/or other products at the same time, the load factor can be much higher.

Logistic can be complex. Trucks may drive from site to site, bringing and returing multiple pieces of equipment. If this is the case, you might workwith the average load factor for the whole logistic operation. If logistic comprise of one transport movement to the job site and an empty return, be sure to include the empty return into the calculation of the average load factor.

The (one-way) distance to a construction site and the number of jobs at construction sites per year should be entered. Note that both the delivery of the product and as well as the pick-up is automatically taken into account in the calculations.

With these four parameters, the Equipment CO2 Calculator calculates the carbon footprint of transporting the product. It can be noted that some of the requested values may differ from case to case or over time. For example, some trucks may be full while others may be empty, and some job sites are further away than others. Therefore, calculated averages or ‘typical’ values can be used to define transport parameters.

Step 5: Maintenance

In Step 5, the user can enter the annual motor oil consumption for the equipment. The motor oil consumption per year is divided in the calculator by the operating hours per year to derive the impact per hour.

In this version of the Calculator it is not possible define the replacement of components. In the weight-based formula, however, we do take into account the replacement of lead-acid batteries (for lead-acid battery powered equipment).

Step 6: End-of-life

End-of-life is the final life cycle phase of a product. The product is disposed of after many years of use, often by various owners. The entire product or its parts may be recycled, incinerated to recover energy, or landfilled.

In the Equipment CO2 Calculator, the approach for end-of-life is comparable to production. The calculator offers two options to determine the carbon footprint of end-of-life:

1. Entering results from an existing LCA (end-of-life only);

2. Using the product’s weight to estimate the carbon footprint.

Recycling of material can lead to a net climate benefit. This is a negative figure (such as: -1.200 kg CO2 eq.). This is because recycling efforts increase the total supply of recycled material. This decreases the need to produce primary materials. This avoided primary production is assigned as a climate benefit.

1. Entering results from an existing LCA

If a LCA has already been carried out for the product that includes a separately shown result for end-of-life, the climate change impact results for end-of-life can be entered in the Equipment CO2 Calculator. If this is the case, it is advised to use this option.

Note that the LCA must meet some conditions to be usable:

- The LCA should report a carbon footprint result. This result is expressed in kilograms CO2 equivalent;

- The LCA result corresponds to one product;

- Ideally, the LCA applies to the specific product being evaluated in the Equipment CO2 Calculator. If an LCA for a similar product is available (with similar weight and material composition), this can be used as a fall-back option. However, this may affect the accuracy of the overall results.

- Scope:

- The entered value should contain only the carbon footprint related to end-of-life. The impact of production (cradle-to-gate; entered in Step 1) and use phase should be excluded;

- The LCA result for the product’s end-of-life may include credits for avoided primary material.

The second option is to use the product’s weight (entered in Step 0) to calculate the impact of the product’s end-of-life. The calculator does this in the background. This calculation is based on the average treatment routes (% to recycling, % to incineration with energy recovery, % to landfill) per material type (metals, plastics, glass, rubber, electronics, wood, insulation material). For most materials recycling is the optimal recycling route, except for wood1.

Recycling leads to avoided production of virgin materials, which is why there is a benefit for end-of-life at optimal recycling.

The calculator offers a range between ‘optimized’ and ‘least optimized’. Least optimized represents either landfilling or incineration and often leads to a net emission instead of an avoided emission.

Please note that using the weight-based approach provides a first estimate of the carbon footprint of product’s end-of-life. It can be used as an indication, but is not as accurate as a product-specific LCA study. However, for many product types, the end-of-life phase is not the most important life cycle stage.

1 Incineration with energy recovery leads to more avoided fossil CO2 than recycling, because there is no fossil CO2-emission while the wood provides energy that is partly recovered and avoids conventional electricity and heat. Note that for other environmental effects recycling may be beneficial. Also, recycling leads to delayed emission of biogenic CO2 but this is not accounted for.

Carbon footprint of a project

The CO2 Calculator offers the functionality to calculate the carbon footprint of a project. Or more precise: of the use of equipment within a project. A project can be large or small, with a short or long duration. Some projects are executed with the use of just one or several pieces of equipment or tools. Large projects, such as entire jobsites, require many different types of equipment, tools and/or accommodation. The impact of a project is expressed in kg CO2-eq per project (or ton or kiloton CO2-eq for large projects). It includes the life cycle emissions of the equipment for the project, plus the transportation specific to the project. You can save your projects on your dashboard. Saved projects can be accessed and edited under ‘Project List’.

To define a project, you complete the following steps:

1. Give the project a name and add a description. If your project has a distinct duration, you may select the start and finish date.

2. Select earlier defined items from the ‘Item List’, that are needed for the project. These items are Construction machines & equipment, Modular and sanitary spaces Smaller equipment and tools, Powered access, forklifts and telehandlers and Power & temperature control that you have defined before. ◦ It is possible to select several numbers of the same item ◦ If an item is not yet present in the list, you can define it

3. Indicate use details for each selected item (type).

4. Define the transport related to the project. The transport is defined per project as a whole, not per piece of equipment.

5. Calculate the results.

Frequently Asked Question

The Equipment CO2 Calculator contains the option to estimate the carbon footprint for the production and end-of-life stages of construction equipment based on the equipment weight, but this estimate does not apply to hand tools or other types of equipment (modular space units etc). This weight-based estimate was developed based on information for larger equipment (1,500 to 15,000 kg). Because hand tools are lighter and composed of different materials, the weight-based estimate can lead to incorrect results.

For other types of equipment outside of larger construction equipment (such as hand tools, modular space units, forklifts, pumps etc.), the calculator can only be used for provided that the user has an LCA from the manufacturer of the specific product is available.

- Equipment weight (in kg)

- Carbon footprint result from an LCA (in kg CO2-equivalent) – optional for construction equipment

- Load capacity of the truck/van carried the equipment to a jobsite (in tonne);

- Truck load capacity factor (as a percentage);

- One-way distance over which the equipment is transported to a jobsite (in km)

- The average number of jobs per year

- Total expected operating hours in total lifetime of the equipment;

- Ownership period (in years);

- Total expected operating hours used during your company's ownership

- Average energy consumption per hour (fuel or electricity)

- Share of biofuels in for fuel or country of use for electricity

- Motor oil consumption (in litres per year)

- Degree by which the equipment is recycled at the end of life

- Grey hydrogen is produced out of natural gas. During the process, CO2 is emitted to air.

- Blue hydrogen is also produced out of natural gas, but the CO2 emissions are captured and stored underground.

- Green hydrogen is produced out of renewable electricity and water. During the process oxygen is emitted, which is not a greenhouse gas.

For more information on hydrogen, consult: https://www.theworldofhydrogen.com/gasunie/what-is-hydrogen/